Hansaplast is one of the world's leading brands in the pharmaceutical wound care sector. Combining high effectivity and safety, as well as excellent quality and medical competency, with an efficient packaging process and eye-catching design is one of the most demanding challenges in the manufacture of these tradition-rich products.

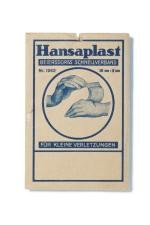

In 1882 pharmacist Paul C. Beiersdorf, together with dermatologist Paul Gerson Unna, received the first patent for the "manufacture of coated bandages". Thanks to this so-called Guttapercha bandage gauze, which was ready to use, adhered reliably and was easily removed, pharmaceutical preparations could finally be applied to the skin and monitored. The Hansaplast brand was launched in the year 1922 as "Beiersdorf's First Aid Wound Cover". Already in 1926, Hansaplast offered its bandages in a special type of packaging — a practical box for sports and travel. Continuous development and innovations lead to never-ending improvements and changes in the bandages, always accompanied by a newly adapted and modernised packaging design.

No.1 in 21 Countries

Today more than 80 products from Beiersdorf are on the market under the Hansaplast brand name for a wide variety of applications. The core of the label is still wound care. Hansaplast is top dog in 21 countries in the "First Aid Bandages" segment. And Hansaplast is unquestionably the market leader in Europe with more than 35 % market share. Further product areas include topical pain relief, bandages, foot care and noise protection.

Packaging Relaunch: Modern and Competent

In the past year Beiersdorf conducted a further packaging relaunch for this global brand. The logo, packaging and design were reworked in order to better accommodate customer needs, also visually. The new logo in bold red and blue is broken by a white arc that reappears in campaign motifs and advertising media. The logo font was also modernised.

Combining modern design with functionality is an absolute must these days. Thus the opening mechanism of the packaging was also reworked in order to simplify the handling and the removal of the bandages. Thanks to situational illustrations on the front of the package, the consumer should be able to recognize immediately which bandage is best suited for which application. The bandage strips are individually wrapped in transparent sealing paper, so that the material, colour and size of the bandage are clearly recognizable upon removal from the box.

Various packaging colours separate the individual product categories from each other: Foot care products are green, the classic bandage assortment blue. The "med silver" bandaging products shimmer in metallic blue.

Less Packaging, More Efficiency

The cosmetic company Beiersdorf AG has its headquarters in Hamburg, employs almost 22,000 staff and achieved 5.97 billion euros in sales in 2008. With Nivea, Beiersdorf also has the world's leading skin and beauty care brand. Next to Hansaplast, brands such as Eucerin, La Prairie, Labello, 8x4 and others are all found in the company's internationally successful portfolio. The subsidiary, tesa SE, is one of the world's leading manufacturers of self-adhesive products and system solutions for industry, business and end-consumers. According to company information, 37 % of all packaging used was made of plastic, followed by glass at 36 %, aluminium (17 %), cardboard and paper (6 %) and combinations at 4 %. As early as 1986, Beiersdorf established an initial project group around the topic of environmentally friendly packaging. Furthermore, Beiersdorf was the first German company to introduce refilling bags for Nivea shower gel in 1992. The amount of packaging material utilized was continuously reduced in the following years.

The latest example is a new sheet metal offset printing press for the production of the approximately 120 million Nivea tins manufactured annually. Thanks to reduced setup time and higher printing speed, the company saves roughly 6 % (120 tons) of the raw material aluminium. Furthermore, the company has been reducing material input in the product and transport packaging for the Nivea for Men Q10 line since 2008: The folded box is now 100 percent recyclable since there is no more window foil used, and 13.2 tons of packaging material is allegedly saved in the production of one million packages.

Source: Interpack

Tel:886-2-28941823 Fax:886-2-28941837 E-mail:viya@packsourcing.com

Copyright Notice © 2015 New Insight Publishing Ltd.. All rights reserved.

Powered by Packsourcing